Modeling and Control of an Electric Arc Furnace

Abstract— Model Based Predictive Control is a class of

computer algorithms that explicitly use a process model to predict

future plant outputs and compute an appropriate control action

through on-line optimization of a cost objective over a future

horizon, subject to various constraints. The cost function is

defined in terms of the tracking error (the difference between the

predicted output and set-point). Using this scheme, many different

MBPC algorithms have been proposed in the literature. This

paper presents an adaptive-predictive control algorithm, which

uses on-line simulation and rule-based control. The algorithm is

applied to an electrode position system of an electric arc furnace.

Electric arc furnaces are commonly used in steelmaking and in

smelting of nonferrous metals. To obtain the electric arc, usually

there are used three graphite electrodes . The power level depends

by the positions of the electrodes. As a result, the realization of a

competitive control system is very important because it led to

reduction of the energy consumption, pollution, and increases the

safety of the process.

I. INTRODUCTION

Model Based Predictive Control (MBPC) designates a very

ample range of control methods that make an explicit use of a

model of the process to obtain the control signal by minimizing

an objective function. The main ideas of MBPC are basically:

-explicit use of a model to predict the process output in the

future;

-on line optimization of a cost objective function over a

future horizon;

-receding strategy, so that at each instant, the horizon is

displaced towards the future, which involves the application of

the first control signal of the sequence calculated at each step.

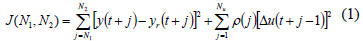

Usually, the cost function is defined by using the output

prediction error relative to the system setpoint and the

weighted control signal, which can lead to a quadratic function

as follows:

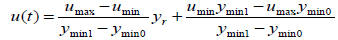

where y[.] is the predicted values of output signal, yr[.] is the

future setpoint, u[.] is the future control signal, N1 is the

minimum predicted horizon, N2 is the maximum predicted

horizon, Nu is the command horizon, ρ(j) is a control-weighting

sequence.

Performance of MBPC could become unacceptable due to a

very inaccurate model, thus requiring a more accurate model.

This task is an instance of closed-loop identification and

adaptive control. The difficulty of closed-loop identification is

that the input of process to be identified is not directly selected

by the designer but ultimately by the feedback controller.

The popularity of model-based predictive control is partially

explained by the fact that it uses traditional dynamic process

models which are usually available for design and/or

simulation purposes. At the same time, model-based predictive

control is being criticized by control engineers because of its

lack or weakness of theoretical background, having no

guarantee of convergence, stability, robustness, etc. in the

general case [1]. The extension of linear MBPC to nonlinear

processes is straightforward at least conceptually. But there

exists some difficulties [2]: the availability of nonlinear models

due to the lack of identification techniques for nonlinear

processes, the computational complexities, the lack of stability

and robustness results. A solution to increase the performances

is to use multiple models [3].

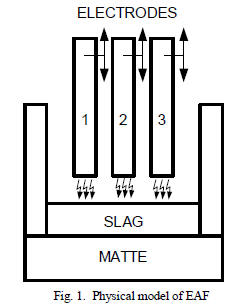

In the metallurgic industry for the melting of the scrap or

other metals it is used the electric arc furnace (EAF). The

electric arc allows to obtain high temperatures necessary to

melt or/and to realize some chemical reactions (fig. 1). To

obtain the electric arc, usually there are used three graphite

electrodes which are supplied by a three-phase power

transformer that has in the primer 20-30 KV respective 100-

800V in the secondary.

The electric power (10…100 MW) depends by the length of

the arc which can be controlled using an efficient hydraulic

control system of electrode position. The circuit closes through

the metal mass that will be molten. The principle needs a very

high-energy consumption, which implies a very efficient

control system to reduce as much as possible energy

consumption. Many times the weight of the electrodes is very

high; it could reach tenth of tons. The hydraulic control system

becomes complex. The acceleration and deceleration imposed

for the electrodes must ensure variable velocities from the

hydraulic control system with the aim of avoiding damage of

the resistance structure.

The electric arc appears when the electrodes are near the

metal mass. To close the circuit, the electric arc must to appear

at least between two electrodes and the metal mass. Usually the

distance between the electrode and the metal mass is 5-15 cm.

The resulted current is initially very high and is the duty of the

control system to move the electrode such that the current is

brought in normal limits. If the length of an electric arc gets

over a certain value, the electric arc extinguishes. In this case,

the positioning system must reposition in the correct form the

electrode so that the electric arc reappears. Another example is

the boiling phenomenon of the metal mass, which leads to a

variable length of the electric arc.

The realization of a competitive control system is very

important because it led to reduction of the energy

consumption, pollution, and increases the safety of the process.

For example, Siemens realized an application that uses

neuronal networks for the optimization of the control system of

the electrodes movement [4]. In addition, there are researches

regarding the use of the adaptive control [5], [6]. Modeling the

phenomenon that takes place in an electric furnace is very

difficult to realize [7]. Close to the hydraulic and electrical

subsystem, modeling can take into account the dynamic

models of the chemical and thermal processes [8] as well as

optimization problems [9].

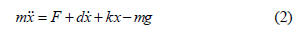

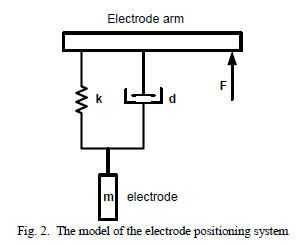

II. THE MODEL OF THE ELECTRODE POSITION SYSTEM

To obtain an efficient control system, it is very important to

understand the mechanics of the hydraulic system that

positions the electrodes. A usual model is presented in [10]; in

this model, the electrode dynamics is modeled as a

combination of a mass, a spring and a damper, as in figure 2.

Thus, the dynamics of the electrodes are represented by a

damped second order system:

In this equation, x represents the electrode position, F is the

hydraulics force, d and k stand for the damper and spring

constants, m is the electrode mass and g is the acceleration of

gravity. Notice that the electrode mass changes, as electrode

materials are consumed during the steel-melting process. Due

to the considerable weight of the electrodes, moving them

upwards requires a much bigger force than in the opposite

direction. As a consequence, when designing an electrode

positioning controller, different gains should be used.

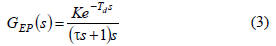

In [11] a simple second -order model of the electrode

positioning system is given by the following transfer function:

where K is the gain factor, τ is a time constant and the

exponential captures a delay of Td seconds. The parameters of

the electrode positioning transfer function were estimated

using measurements in closed loop.

III. A MODEL BASED PREDICTIVE CONTROL ALGORITHM

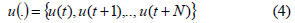

In [12] it was proposed an algorithm designed for

applications with constant setpoint (but arbitrary changed). The

main idea of the algorithm is to compute for every sample

period:

- the predictions of output over a finite horizon (N);

- the cost of the objective function (1),

for all (theoretically case) or a few (practically case) possible

control sequences:

and than to choose the first element of the optimal control

sequence.

For a first look, the advantages of the proposed algorithm

include the following:

-the minimum of objective function is global;

-it is not necessary to invert a matrix, therefore potential

difficulties are avoided;

-this algorithm can be applied to nonlinear processes if a

nonlinear model is available;

-the constraints (linear or nonlinear) can easily be

implemented.

The drawback of this scheme is a very long computational

time, because there are a lot of possible sequences. For

example, if u(t) is applied to the process using a “p” bits

digital - analog converter (DAC), the number of sequences is

2p*N . Therefore, the number of sequences must be reduced.

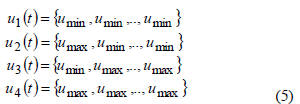

For a first stage, there were proposed the next four control

sequences:

where umin and umax are the limits of the control signal.

Using these candidate control sequences it results four

output sequences y1(t), y2(t), y3(t), y4(t).

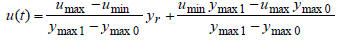

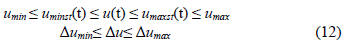

The control signal is computed using a set of rules based

on

the extreme values ymax0, ymax1, ymin0, ymin1

(fig. 3) of the output

predictions. It is considered four usual cases (yr is the setpoint,

d is dead time, t1=N):

Case 1: If :

ymax0<yr (corresponding to u1(t) sequence)

ymax1>yr (corresponding to u2(t) sequence) (6)

Then:

Case 2: If:

ymin0<yr (corresponding to u3(t)

sequence)

ymin1>yr (corresponding to u4(t) sequence)

Case 3: If:

ymax0>yr (corresponding to u1(t)

sequence)

Then u(t0)=umin

Case 4: If:

ymax1<yr (corresponding to u2(t)

sequence)

Then u(t0)=umax

In fig. 3, every output prediction curve is marked with a

number which corresponds to the number of control sequence

from relations (5). Analogous to case 3 and case 4, there are

two similarly cases if dy/dt<0 for t<t0.

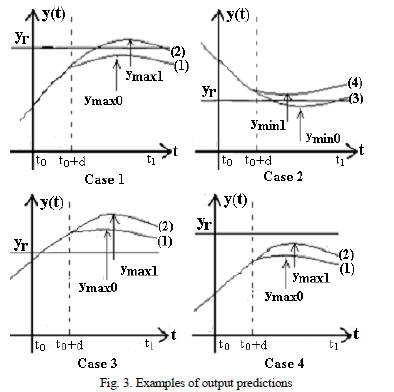

In the second stage, depended by the behaviour of the

control system, it is used an algorithm that modifies the limits

of control signal:

In relations (5)…(11), the values of umax, umin

are replaced

with uminst(t), uminst(t).

IV. THE CONTROL OF THE SYSTEM

The previous sections indicates the fact that the modeling

of

the process in an electrical arc furnace it is difficult to be

realized and exists more aspects that cannot be sufficient

known.

During furnace operation, the characteristics of the bath

change as the solid scrap melts into liquid steel, until metal

pool. This leads to large changes in the charge conductance; it

is possible to consider this variation as a disturbance to the

process. The main disturbances to the process are due to scrap

movements, mainly in the beginning of the melt-down, when it

not exists a liquid bath. As a result, some times the scrap

touches the electrodes, which cause short circuits. Another

problem is the strong coupling effect between the electrodes.

This means that when the position of one electrode is changed,

the currents in the others also changes.

As a consequence of the parameter variations of the

process

as well as the fact that the process’s model can present many

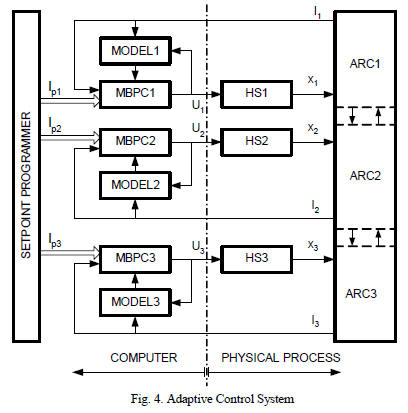

unknowns, it is justified the usage of the adaptive control. In

what it follows, it will be made the assumption that each

associated subsystem to the three electrodes may be

approximate by a linear parametric model with unknown

parameters that follows to be on-line identified. In figure 4 it is

presented the bloc scheme of the proposed control system.

Used notations:

-MBPCk, k=1..3 - model based predictive control

algorithm;

-Modelk, k=1..3 - subprocess model of electrode positioning;

-HPk, k=1..3- k hydraulic subsystems;

-x1..x3 – positions of the three electrodes;

-I1p..I3p – setpoint values of the currents on the three

branches;

-I1..I3 – electrical currents on the three branches;

-u1..u3 – command signals of the hydraulic actuators;

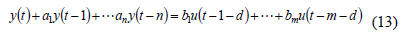

It is used a linear model of the form:

where y[.] is the output signal (electrical current), u[.]

is the

control signal (command signal of the hydraulic actuators), n,

m define the model dimension, d is dead time, ai, bi are

process’s model parameters.

In the practical implementation, the control algorithm

will

receive as input data the measured currents on each electrode

(these currents depend obviously also on the length of the

electric arcs) but also information concerning the electrical

voltages measured on arcs. The adaptive control algorithm will

assure control signals u1, u2, u3 necessary for

desired

positioning of the electrodes in such a way that by each branch

to be realized the prescribed electrical current. The signal pairs

(uk, ik – k=1..3) are used by the Modelk,

k=1..3 blocks to

realize the experimental identification of the parameters of the

three models. Identification may be realized by example by

using the recursive least square algorithm.

Certainly, on the experimental basis it must be

established a

sampling period, the dead time and the parameters that define

the dimensions of the model process (n, m).

To be able to test (by simulation) the proposed system,

the

process has to be simulated (including the hydraulic part). For

the electrical part it will be adopted a model in direct current

that although it is very simple, it leads to obtaining of some

nonlinear calculus relations. It is considered that, in conditions

that the arc is active, and then its resistance is proportional with

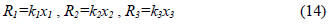

its length:

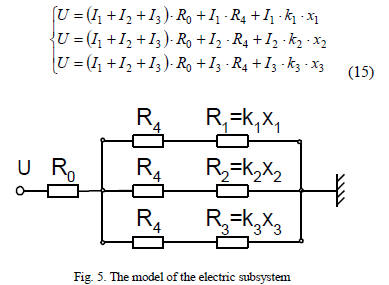

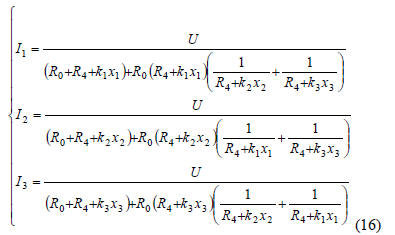

In figure 5 it is presented the simplified scheme of the

electrical parts. It can be written the following relations:

Solving this system it is obtained:

Taking into account the equations (2) and (3), for

modeling

the hydraulic subsystem that can be used the equation forms

(13) in which can be choose the structure parameters (m, n, d)

as well as the model parameters ai, bi.

Let’s make some remarks:

- usually it may be considered k1=k2=k3; it was

used the

different coefficients to study what’s going when the forming

conditions of the electrical arcs on the three electrodes differs

due some known or unknown reasons ;

- in a real implementation, the output of the hydraulic

system

respectively the distances between the heads of the electrodes

and melting are not known. The output signals from the

process are currents and voltages of these can be measured.

- for simplification of the application, there will be

considered as the output signal from the process that will be

controlled, the electrical currents through the three electrodes.

It has to be mentioned although, that usually are controlled the

impedances on each channel or the consumed on each canal [7], [13];

- due to the way in which it is formed or are extinguished the electrical arcs, the control algorithms must use a set of rules that it implements the different conditions. Let us consider the initial phase in which all the electrodes are far from the metal mass. It may be taken into account different strategies of approaching the electrodes of the metal mass. In the moment in which one of the electrodes reach the metal mass, this thing may be seen (I≈0; Uarc≈0) and the motion of the electrode must be stopped. When the second electrode reaches the metal mass, there are created the conditions for activation of the electrical arcs that leads to the appearance of the very large electrical currents. The control system will have to position the two electrodes thus the electrical currents to have the desired value. Activation of the third electrical arc will be made if the distance from the electrode and metal mass is sufficient small. In a similarly way it has to be adopted strategies for situations that can appear: extinguished the electric arcs, reaching the electrodes to the metal mass etc.

- due to the particularities of the process, the identification operation of the process parameters will be deployed only when there are fulfilled some certain conditions (e.g. all the electrical arcs must be activated).

The model process may be used for on line simulation of the system’s behavior for a number of control sequences.

By analysis and interpretation of the resulted output sequences, it is possible to compute the control signal considered optimal at the respective moment. Such an algorithm that uses on-line simulation and rule-based control is presented in [14], [15], [16]. The algorithm has the advantage that permits the direct use of the nonlinear model of the process and permits easy implementation of some conditions presented previously.

V. SIMULATION EXAMPLE

Based on what was previously shown, it was realized an application [17] that permits simulation and testing the identification algorithms and control. Application permits:

- choosing the type of the algorithm (On-Off, PID, adaptive-predictive) used for controlling the position of each electrode and choosing some parameters of the control algorithms;

- choosing the process parameters: order (np, mp, dp) of the hydraulic system, the characteristics of the electric system (r0, r4, k1, k2, k3 from fig. 5), volumetric efficiency of EAF;

- choosing the order of the process model as well as of some parameters of the identification algorithms (forgetting factor etc.);

-introduction of some perturbations: interrupt arc, scrap break down, random length of the arc, noise on current measure, changes on scrap surface.

The user can modify during the simulation most of the control algorithm parameters and of identification, the process characteristics; it can be chosen different algorithms of control for the three electrodes.

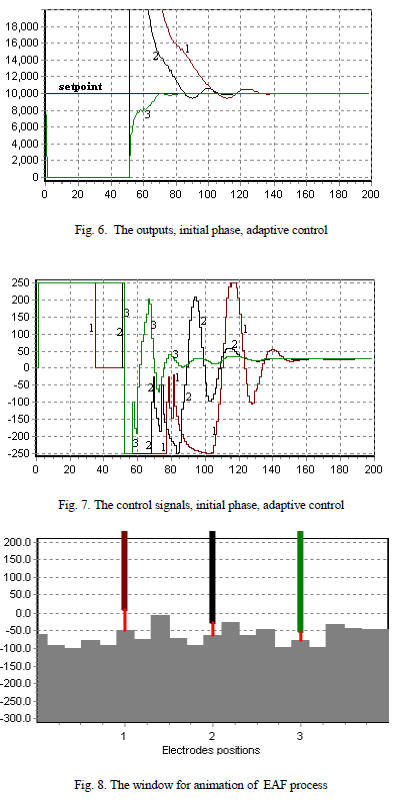

In fig. 6…8 is presented an example of evolution of the outputs (electrical current) of the control signal as well as the window for animation of the EAF process. It was used model based adaptive control. There are used different coefficients (k1=0.0003, k2=0.0005, k3=0.0007). It was noted 1, 2, 3 the corresponding electrodes signals 1, 2, 3.

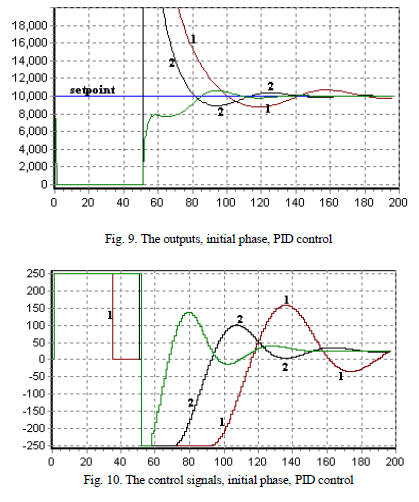

In fig. 9, 10 are presented the behavior system in the case of PID controller’s usage.

VI. CONCLUSIONS

In this paper were presented some aspects concerning the modeling and adaptive control of the position of the electrodes in an electrical arc furnace. The realized application [17] permits testing the control algorithms, study of the error effects on modeling, simulation of perturbations etc. For facilitating the practical implementation, application can be developed by extend of the possibility of choosing the component subsystems, using the multiple models, optimization strategies, etc. Application was realized by using Delphi environment, also used in other control applications for EAF [18]. Taking into account the complexity of the problems, an approach that will be used in the future includes usage of the Matlab-Simulink modeling and simulation environment [19] as well as dSpace equipments [20] for testing the ECU.

ACKNOWLEDGMENT

This work was supported by the Ministry of Education and Research grant CEEX 112 INFOSOC program. Grant’s title: Simulation, Control and Testing Platform with applications in Mechatronics.

| Prev | Next |